Fiber laser cutting machines currently have a dominant presence in sheet metal cutting and forming (cold working) shops.

They have succeeded in relegating the traditional CO2 lasers to the machining of non-metallic materials such as plastics, glass, acrylic, wood, textiles, etc.

This fact is based on the significant advantages of fiber laser technology compared toCO2 lasers.

Advantages of fiber laser cutting over other laser cutting technologies

- Small footprint: Fiber laser generators are compact and take up little space compared to generators of equivalent power inCO2 lasers.

- Profitability: Due to the lower prices of these machines, their high energy efficiency and extremely low maintenance costs, fiber laser cutting machines are 4 to 5 times more profitable than machines with other metal cutting technologies.

- Simplicity: The conduction of the beam through the fiber greatly simplifies the adjustment and maintenance of the machine compared to traditional optics, which required periodic adjustment and cleaning, which was very complicated.

- Accuracy: Fiber lasers allow the light beam to be concentrated in a smaller spot, achieving more efficient and precise cuts.

How does a fiber laser cutter work?

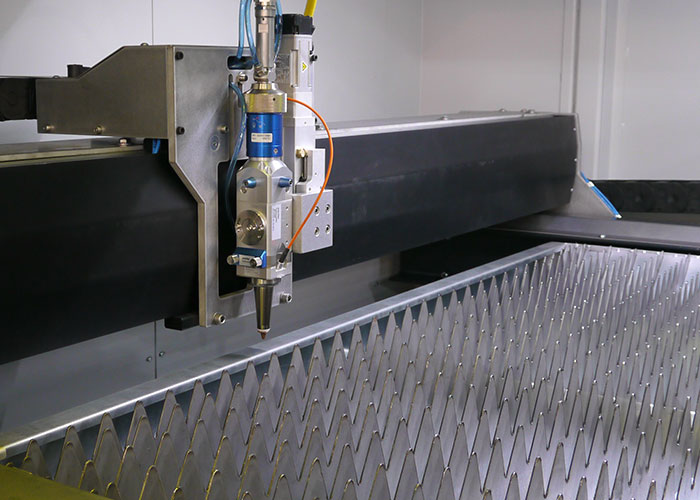

Fiber laser cutting of metals is produced by a high concentration of energy in a very small spot. This concentrated energy produces the alteration of the material, which melts or vaporizes.

Depending on the material to be cut, gases (mainly oxygen or nitrogen) are applied at the incision point of the beam to assist combustion or expulsion of the molten material.

How powerful does a laser need to be for cutting metal?

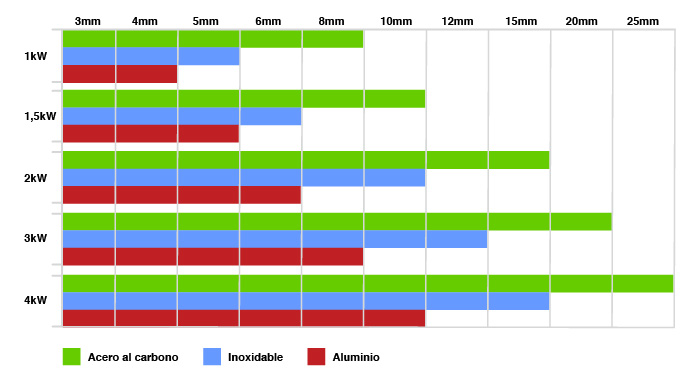

The power required to cut a material will depend on the type of material and its thickness. There are other variables that can condition the power required, such as, for example, the composition of the material, its temperature, the cutting speed or the state of its surface. However, we can take the following table as a reference:

There are high power equipment (up to 30kW) that can cut large thicknesses, but they are usually used for very specific and marginal needs.

Types of metal laser cutters

Depending on the format of the raw material to be processed, there are different types of cutting machines:

- Formatting machines configured according to standard sheet formats, such as 3000x1500mm, 4000x2000mm or 6000x2000mm, which are very common in the industry.

- Machines fed with metal coil, with configurable coil width. These machines offer a high autonomy as they can operate for a long time without the intervention of an operator.

- 3D cutting machines for operation on three-dimensional parts.

- Tube laser cutting machines that allow to operate on the different faces of tubes, beams and profiles.

What should we consider when buying a metal laser cutter?

There are different ranges of machines in terms of power, working area and quality of their components. All this translates into a wide range of prices.

It is important to be clear about what work we need to perform and to adapt the machine’s capacity to our needs. There are machines for high production with automated sheet loading, even with integrated autonomous sheet storage. On the other hand, there are more compact cutters for small workshops that only require internal use for their own production.

We must also take into account the reliability of the components mounted on the laser cutting table. At Motocono, we only mount top level components, such as IPG resonators, Precitec heads or linear motors for the transmission of movement to the axes, among others.

It is of vital importance to take into account the quality and effectiveness of the technical service. The support of the manufacturer of your fiber laser machine can be decisive in case of any unforeseen event. In Motocono, as manufacturers and installers of our equipment, we offer constant support to our customers, especially in the first months in which the user is in a period of learning and adaptation.

Further reading: Types of lasers for industrial applications

Still have any doubts about how a fiber laser cutter can help boost your business?

¡Contact us at without obligation!